智能工厂测量系统解决方案(SFIS)

SFIS COMPONENTS

- Modular in design, and scalable in size production inspection cell.

The CHECKBOX modular enclosure design allows system size to be configured to suite each customer’s specific measurement task while providing a standardized solution.

CHECKBOX ENCLOSURE

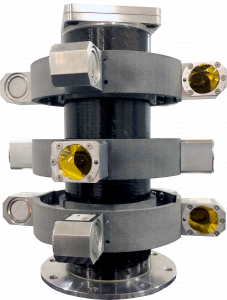

RAPIDSCAN HYBRID OPTICAL SENSOR

- Capable of measuring highly reflective and composite surfaces RapidScan completely eliminates the need for impractical production part spraying.With sub pixel edge detection, the (hybrid pattern) optical projection generates a highly accurate dense point cloud.

API’s RAPIDSCAN ultra-high dynamic range, 3.2 mega-pixel, stereo imaging, hybrid optical sensor captures a 3D point cloud of the part within its large field of view.

API RADIAN PRO LASER TRACKER

- Unrivaled accuracy and comprehensive functionality including automated 6DoF tracking.

The RADIAN PRO IFM/ADM laser tracker continues API’s more than 30 year legacy of pioneering laser-based equipment for measurement and calibration offering the smallest, lightest, and most accurate portable trackers on the market.

SFIS SOFTWARE

- Intelligent run-time software.

The SFIS software supports the robot, laser tracker, optical sensor and measurement function in one simulation environment. Inspection paths are automatically generated from part CAD data with interactive robot measurement path definition based on optimum sensor scan-angle and standoff. Automatic checking of SMR targets visibility in planned inspection path and seamless loading and application of the simulated path to the online measuring process.

6DoF Tracking System

- – Smart Tract System

– SMR Extension Tube

– SMR PlateAutomatic checking of SMR targets visibility in planned inspection path and seamless loading and application of the simulated path to the online measuring process.

DOWNLOAD OUR CHECKBOX BROCHURE